Any customer can have a car painted any colour that he wants, so long as it is black.

Henry Ford

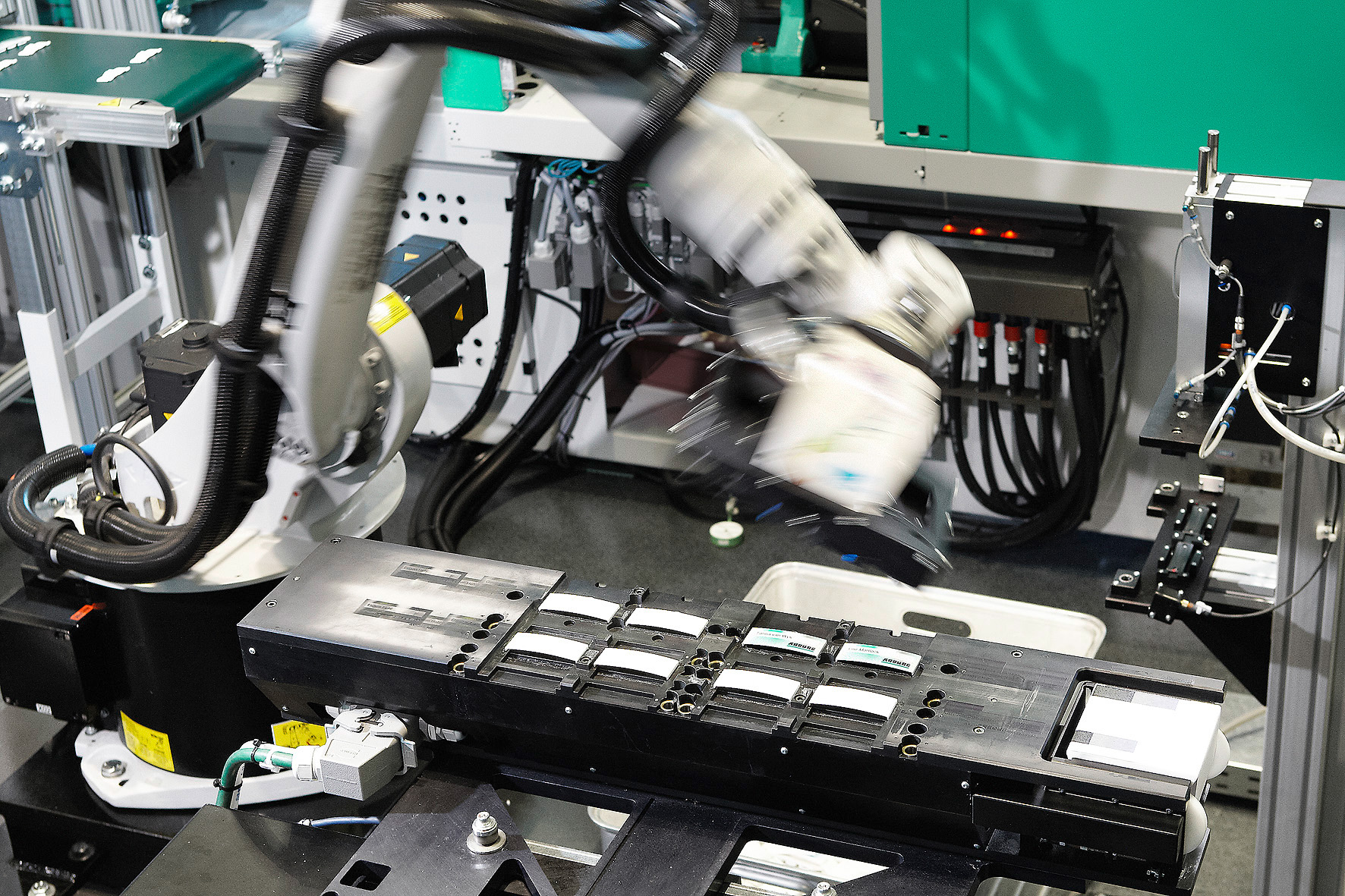

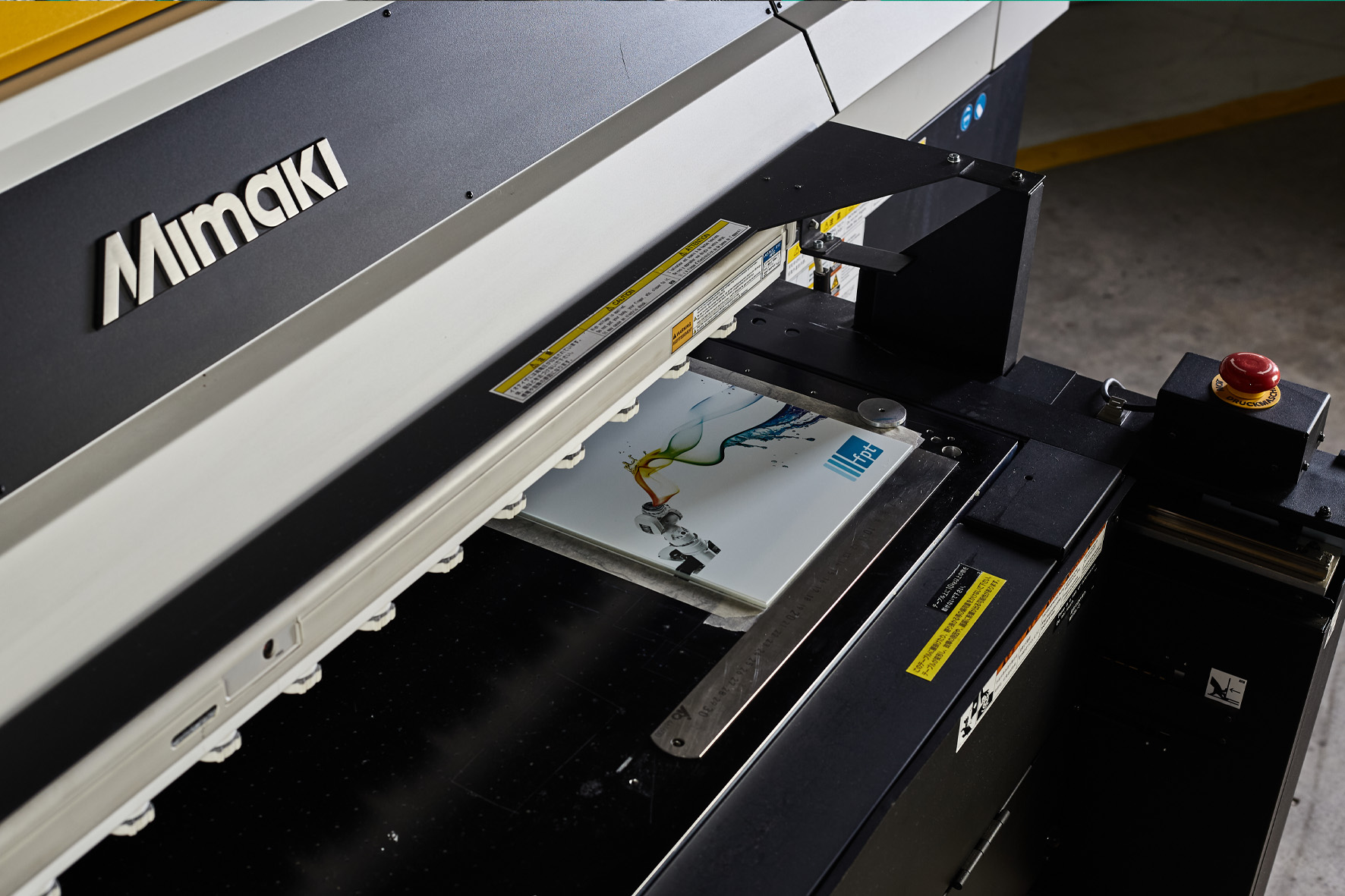

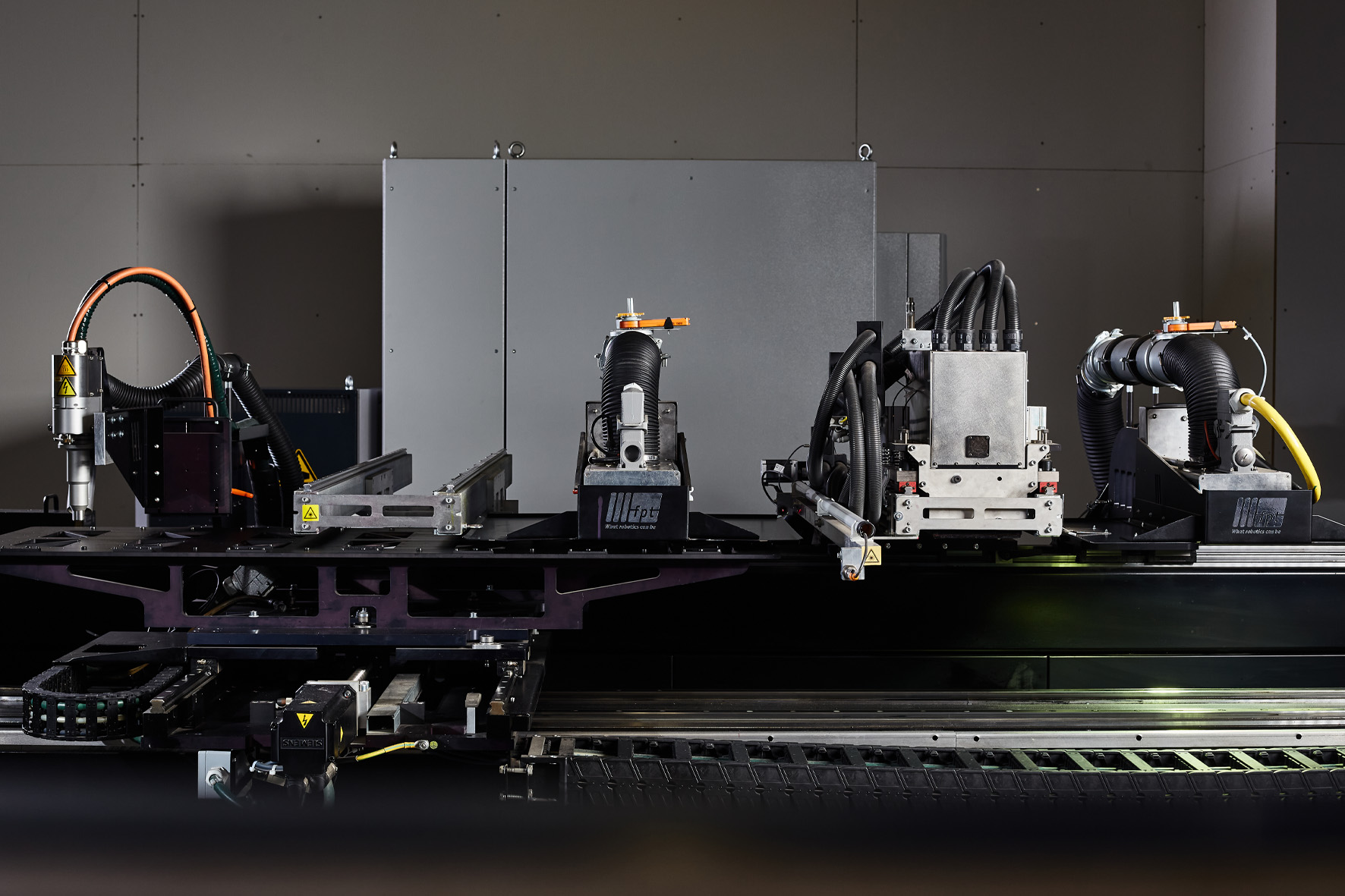

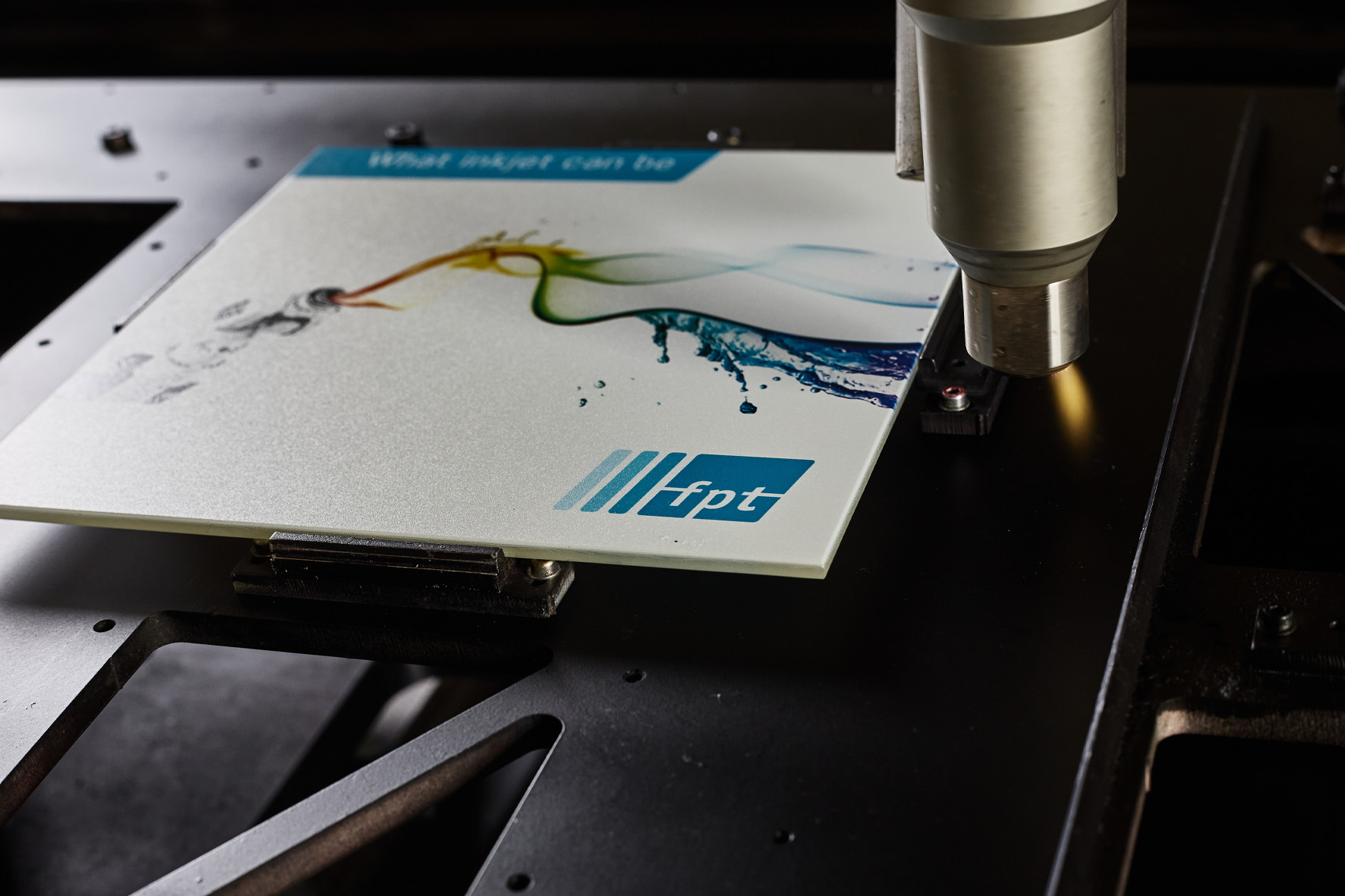

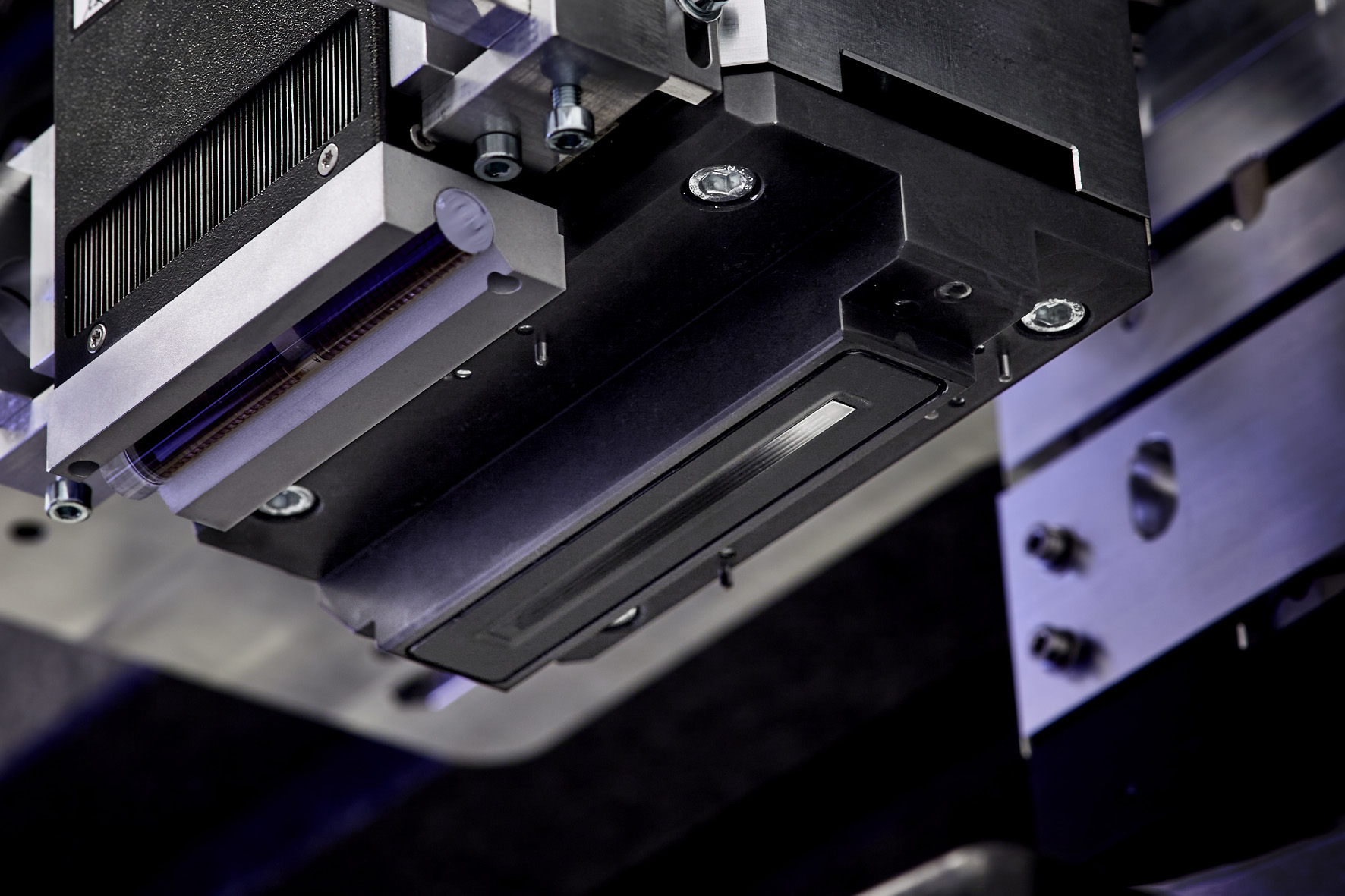

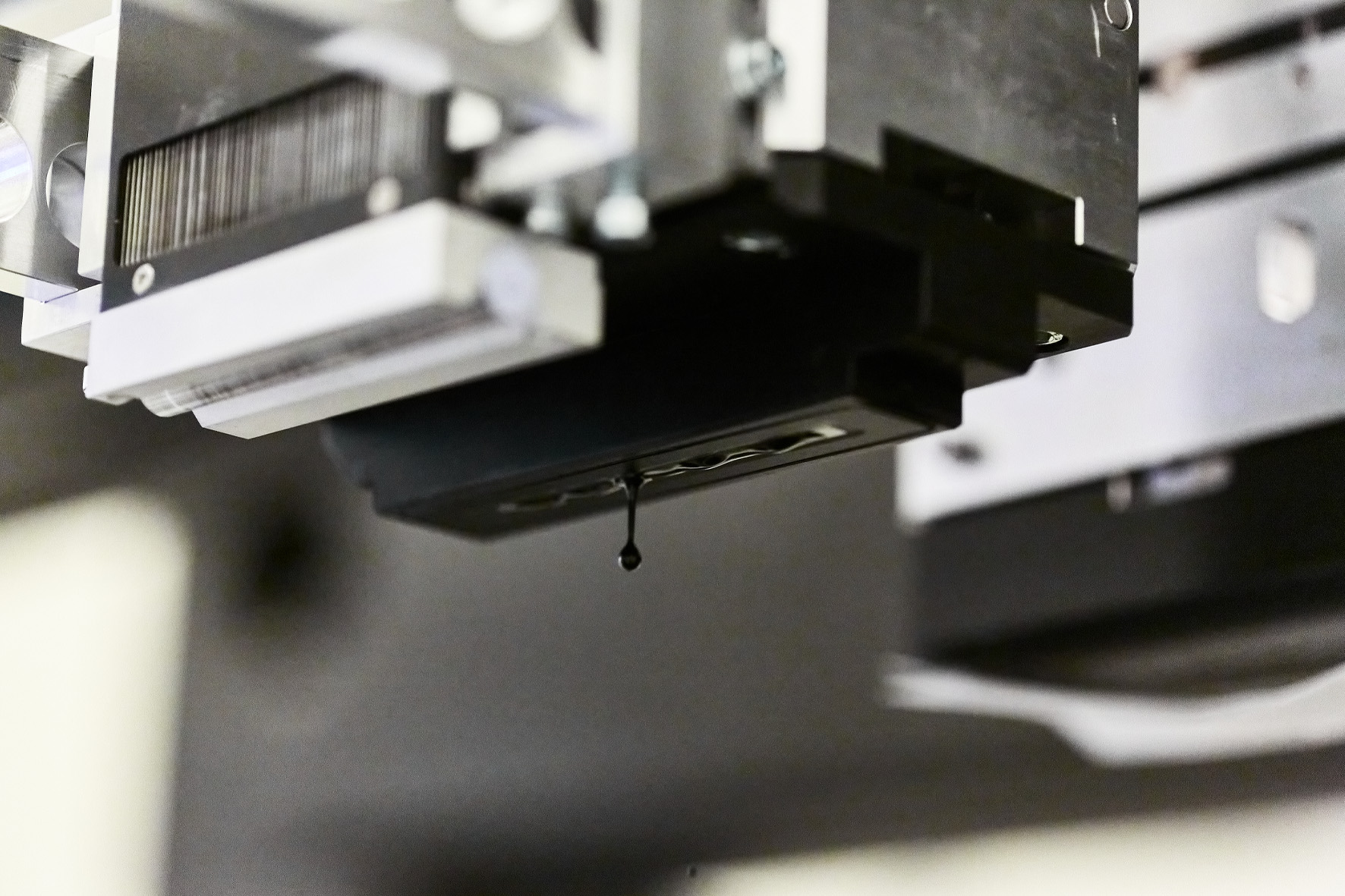

Back in 2009, we developed the InkBOT - a synthesis of robotic kinematics and digital printing technology. More than 10 years of development work and a multitude of reputable digital printing solutions later, a new technology is created: digital free-form printing. It combines the economic advantages of mass production with the trend of individualization. Today, we support you - from the initial idea to 24/7 production - as a general contractor in taking advantage of the opportunities offered by this unique solution for your company.

DE

DE EN

EN